Made in Minnesota: Anchor celebrates centennial anniversary

Minneapolis — Anchor Block Company celebrates 100 years in business as a Midwest manufacturer of concrete construction and landscape materials. Founded in the Twin Cities, the company began in 1909 at a time when homebuilders dug foundations by hand and used horses to haul Anchor’s standard gray, concrete basement blocks. Today, Anchor is recognized worldwide for its extensive line of innovative products and inspired applications.

Anchor historic photo

In the Midwest, Anchor Block Company is well-respected for its industry leadership and long-standing partnerships with contractors, architects, engineers, dealers and retailers. Anchor produces traditional concrete masonry blocks, architectural masonry blocks and veneers, retaining wall blocks, pavers and other landscape products. Two of the most recent, notable, local building projects featuring Anchor’s products include Target Field, the Twins’ new ballpark, and TCF Bank Stadium, home to Gophers’ football. Other metro-area icons include Mall of America, Metrodome, Target Center, University of Minnesota’s Carlson School of Management and several other campus buildings, plus thousands of Minnesota community spaces, private homes and commercial businesses.

“The fact is that a lot of people don’t think concrete is beautiful, but that’s before they see the color, textures and shapes available for them to create inviting, outdoor, private retreats and public destinations,” says Glenn Bolles, CEO of Anchor.

He recalls a time before such options, “Until the ’80s, color choices were non-existent; everything was gray. In the mid-’80s, integral-colored concrete changed the industry overnight. We incorporated this into our retaining wall products, pavers and masonry products. Soon, we were seeing colorful walls and paths in all directions. Until the early ’90s, you hardly ever saw a driveway made of colorful, paving stones in Minnesota. Now, they are everywhere. People are building something beautiful with our products all over the Twin Cities.”

“Today, we have more than 100 dedicated, committed and terrific employees,” says Bolles. “We’re financially solid and plan to be in it for the long run. We’re investing in new equipment and technologies that will help us continue to lead the industry. We’re listening to our customers, and working really hard to come up with even more attractive products and solutions. We want to deliver what the customer is asking for, and anticipate what they will ask for. Sometimes, they need to see what we have to offer before they know they want it.”

Solid Reputation

“We’ve used Anchor from the beginning, so it’s at least 40 years,” says Michael J. Gresser, president of specialty contractor Gresser Company. Based in Eagan, Minn., Gresser is one of many Twin Cities companies that share an intertwined heritage with Anchor. “We’re known for our quality standards and quality work. We can’t maintain that reputation if we’re not installing quality product.”

Gresser and Anchor both worked on the TCF Stadium. Highlighting another project example, Gresser praises Anchor’s involvement with BMW of the Twin Cities. “We’re working in Minnetonka on BMW’s second major Twin Cities dealership. The first was in Bloomington. For both, the owner was very specific about wanting a white, white block. We knew we could count on Anchor to meet these requirements. …Anchor is, without a doubt, our most-valued block supplier. They have a lot more consistency in the quality of their product. We appreciate the quality and consistency in their people, and in their delivery. They’re great to work with, a first-class company and our vendor of choice.”

Anchor Block Co archive image

Tim McGough, executive vice president of McGough Companies, Inc. in St. Paul, Minn. agrees, “As long as we’ve been in business, Anchor has been there for us. Throughout our 55-year history, Anchor has been a great business partner. Like us, they take pride in building long-term customer relationships. …Today, they are our primary supplier of concrete block and related products. Their customer service is incredible. Their delivery is always prompt. Their product is always high quality. And, their quality control is outstanding.”

Innovation by Design

Anchor staff engineer Bruce Baumann credits Bolles for Anchor’s ability to achieve this reputation and preserve this status in a down economy. He says, “Glenn’s passion to be the leader is matched by his willingness to invest in the research and testing to maintain this position. It may be tough now, but we’re using this time to work on new products and applications. We’re exploring new materials and continually searching for new looks, colors, textures, shapes and sizes.”

Both Baumann and Bolles cite Windsor Stone® blocks as a “grand-slam homerun” in their history. “Designed for garden walls, planting containers and small retaining walls, the Windsor Stone product has a traditional, beveled face style. And the rear lip design makes installation easy—you just stack and align the blocks,” describes Baumann.

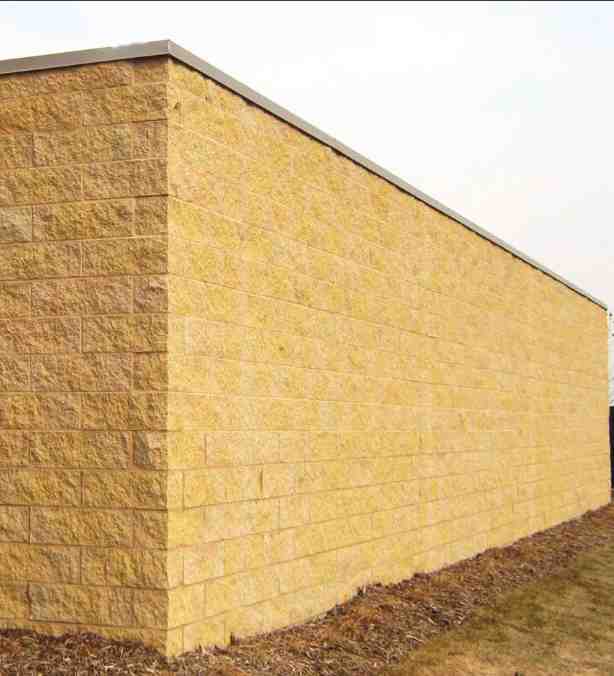

Baumann’s enthusiasm for Anchor’s product developments is obvious as he describes the proprietary technology that creates the Old World look and rock face texture of its Highland Stone® Retaining Wall System, or Anchor’s Sculpsit™ technology that earned it “Top Innovator of the Year” awards from The Home Depot two years in a row.

“At the moment, we’re having a lot of fun simulating stone-like colors and textures,” says Bolles. “The industry is changing as I speak: our Sculpsit technology will help everybody who wants the look of natural stone, but not the expense. There’s very little difference in appearance and a significant price savings for the installed Anchor™ product.”

This year, Anchor has introduced several new products in retaining walls, pavers, patio stones and edgers. The company has new designs and product enhancements already planned for 2010 and beyond. According to Bolles, most companies in the industry “might launch one new product a year, or maybe one every several years. Of course, if you don’t have new, state-of-the-art equipment, you have a hard time delivering new products.”

Tested for Success

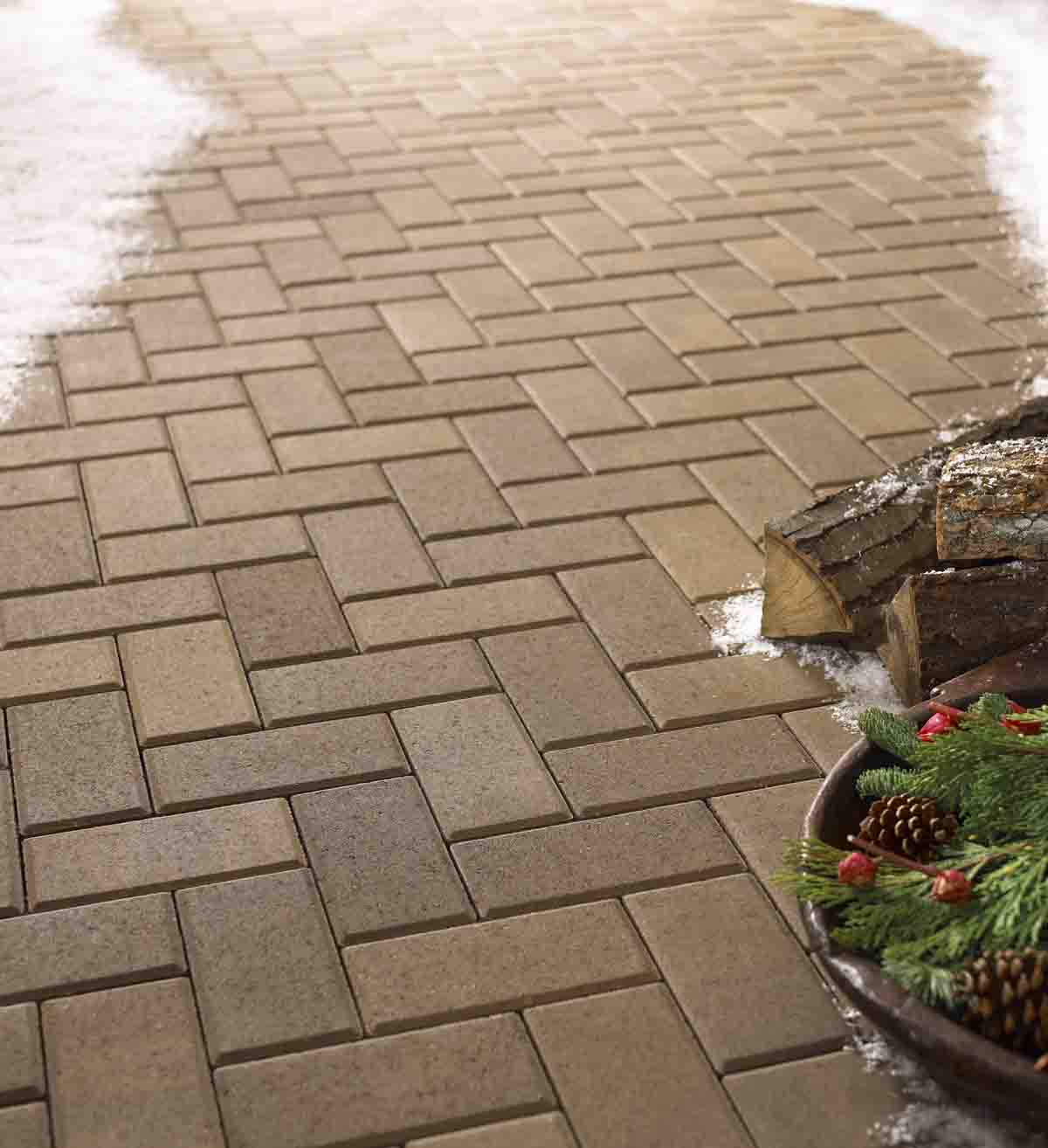

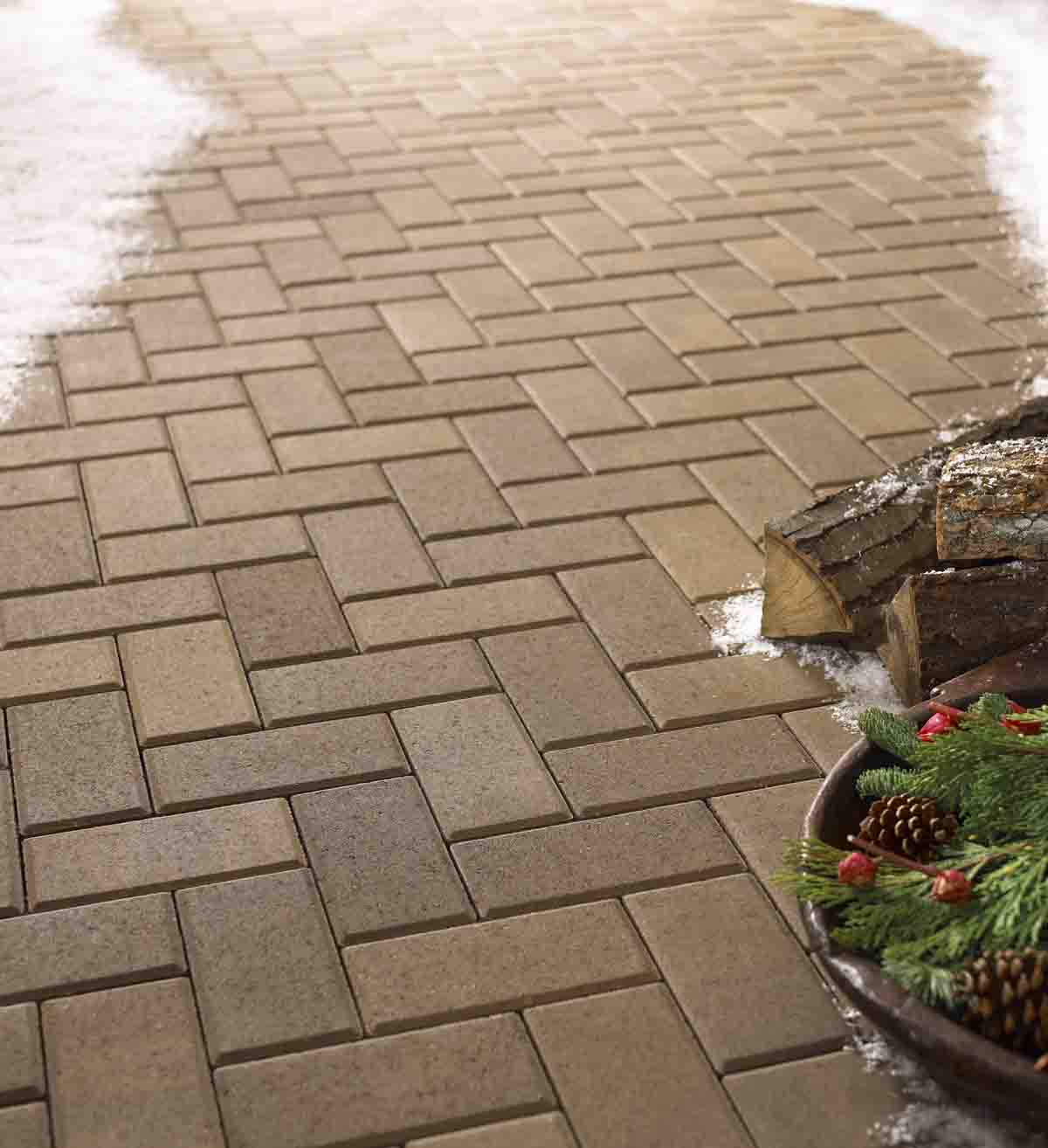

Long-term performance is another area of Anchor’s study. “Freeze/thaw durability is critical to the northern two-thirds of our country and particularly with segmental retaining walls,” says Baumann. “Having one of the industry’s largest, in-house quality control laboratories, we can more readily test products. This allows us to optimize them, continually improving upon our past and directing future quality.”

Anchor's Holland Plus™ Pavers

“Our Plus™ series of pavers is the first in the Midwest to provide concentrated, premium material on the surface of the pavers so that it produces a richer color, distinctive, fine texture and wear-resistant surface,” says Bolles.

The durability and green attributes of Anchor’s products are generating greater interest among the architectural and landscape design community. Anchor’s landscape and masonry products contain as much as 20% recycled content, which can help buildings qualify for certification under green building programs like LEED® (Leadership in Energy and Environmental Design). Anchor’s product attributes also can meet green building qualifications for stormwater design and control, heat island reduction, energy performance optimization and regionally sourced materials. The products’ sound-dampening, mold-resistant, and durable qualities also may be recognized for sustainable application and innovation.

Shared Paths

According to Bolles, the introduction of landscape products in the late 1980s changed the direction of the company. The signature breakthrough came in 1988 when Anchor invented and patented a pinless, mortarless segmental retaining wall (SRW) block. The success of this design made Anchor a pioneer in the SRW industry. In 1989, Anchor Wall Systems, Inc. was formed to capitalize on the growing national and international demand for SRW systems.

Anchor archive image

“We have a shared ancestry. Anchor Block Company is a manufacturer and Anchor Wall Systems is a licensor of technology,” explains Linda Luksan, director of marketing for Anchor Wall Systems. “We license the rights to produce and sell our products to Anchor Block and other manufacturers. Anchor Wall Systems works with more than 50 companies in 21 countries to bring our retaining and freestanding wall systems to their markets.”

Natural Response

Anchor Block’s masonry and landscape products are sold through dealers and home centers throughout the state and in Iowa, South Dakota, North Dakota, Wisconsin and Nebraska. “Anchor Block’s Midwest territory serves as a pilot facility testing new concepts, installations and our first place to roll out new products. These products are sold to everyone from small, residential do-it-yourselfers to contractors hired by the homeowner to create elaborate, outdoor living spaces,” adds Sandy Stoffel, director of marketing for Anchor Block Company. “With the economy being what it is, people are staying close to home. As they’re home more, they want to make it nice and are justifying home improvements that beautify their backyards.”

Anchor's Bravissi products

According to Stoffel, “Inspired by European roadways, Anchor entered into the paver market in 1999 and has continued to develop new products, colors and textures to bring consumers multiple choices that provide aesthetics and quality to walkways, driveways, and patio settings.” Drawing additional inspiration from classic, hand-chiseled masonry, Anchor recently developed Bravissi™ Sculpted Masonry Veneer products, a line of cost-effective, highly realistic stone-look veneers.

To complement the simulated look of natural stone, Anchor Block offers a burnished block that is popular with its customers. Masonry sales manager Mark Severson observes, “A highly polished, beautifully exposed aggregate finish for a distinctive look, burnished block offers stunning coloration effects. With advancements in our color capabilities, we have some exciting new looks ahead.” Anchor’s full product line offers more than 7,000 color, shape and texture combinations.

Faster, Safer, Better

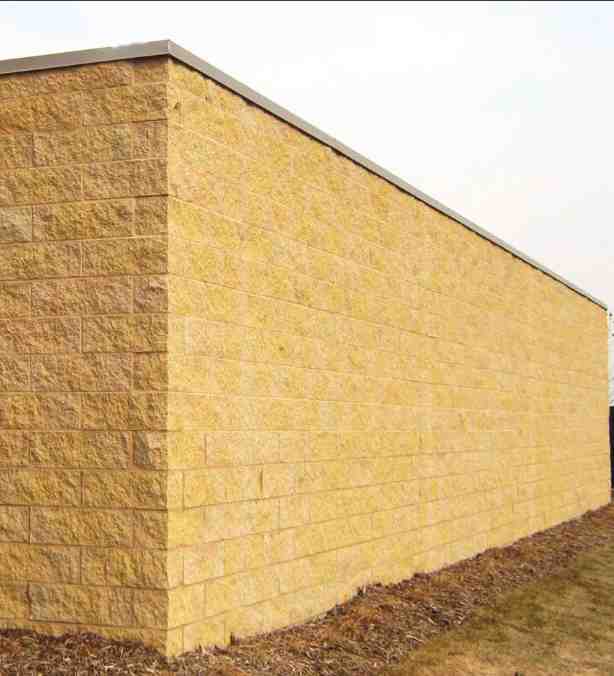

Severson continues, “As we’re moving away from the common block look, we’re also moving more and more to larger sizes. Contractors want to save time. Typically, you’d see them installing an 8″x16″ face, but we have sizes that range from 8″x24″ to 12″x24″, up to 16″x24″. At 24 inches, structural block can help shorten development schedules by covering more space with fewer blocks.”

Anchor's Tufut products

Pronounced “Two Foot,” Tufut™ Structural Concrete Masonry Units were introduced earlier this summer in a variety of solid and variegated colors. Helping to meet tight construction timelines, Tufut blocks install up to 30% faster and require less grout than smaller units. Each two-foot-long unit covers 50% more wall area per unit than conventional blocks.

Anchor Celebrates

Anchor is celebrating its centennial year with events and picnics throughout the company. Bolles reiterates his appreciation, saying, “Anchor values its employees and their contributions to our success over the years.”

###

Filed under: CLIENT NEWS | Comments Off on Client News 11/23/09