Toledo’s Hawkins Elementary strives for LEED Gold, using Wausau’s windows

Hawkins Elementary, Toledo

When Toledo Public Schools opened Hawkins Elementary last month, it was difficult to tell who had the biggest smiles: the students who would be the first to occupy the building, the teachers and staff who would enjoy working in classrooms filled with natural sunlight, or the community members who supported the area’s first, “green” school building.

Hawkins Elementary is part of Toledo Public Schools‘ (TPS’) Building for Success program, which will rebuild or renovate more than 50 area schools during a 12-year period. Built at a cost of $11.4 million, Hawkins is the ninth TPS building designed by the Collaborative, a group of local architectural and engineering firms formed to work together on Building for Success.

The 60,000-square-foot educational facility now is home to nearly 500 students, teachers and staff. Located at 5550 W. Bancroft Street in west Toledo, Hawkins also is the first TPS building registered to attain a Gold Level rating from the U.S. Green Building Council’s Leadership in Energy and Environmental Design® Green Building Rating System™, known as LEED for Schools.

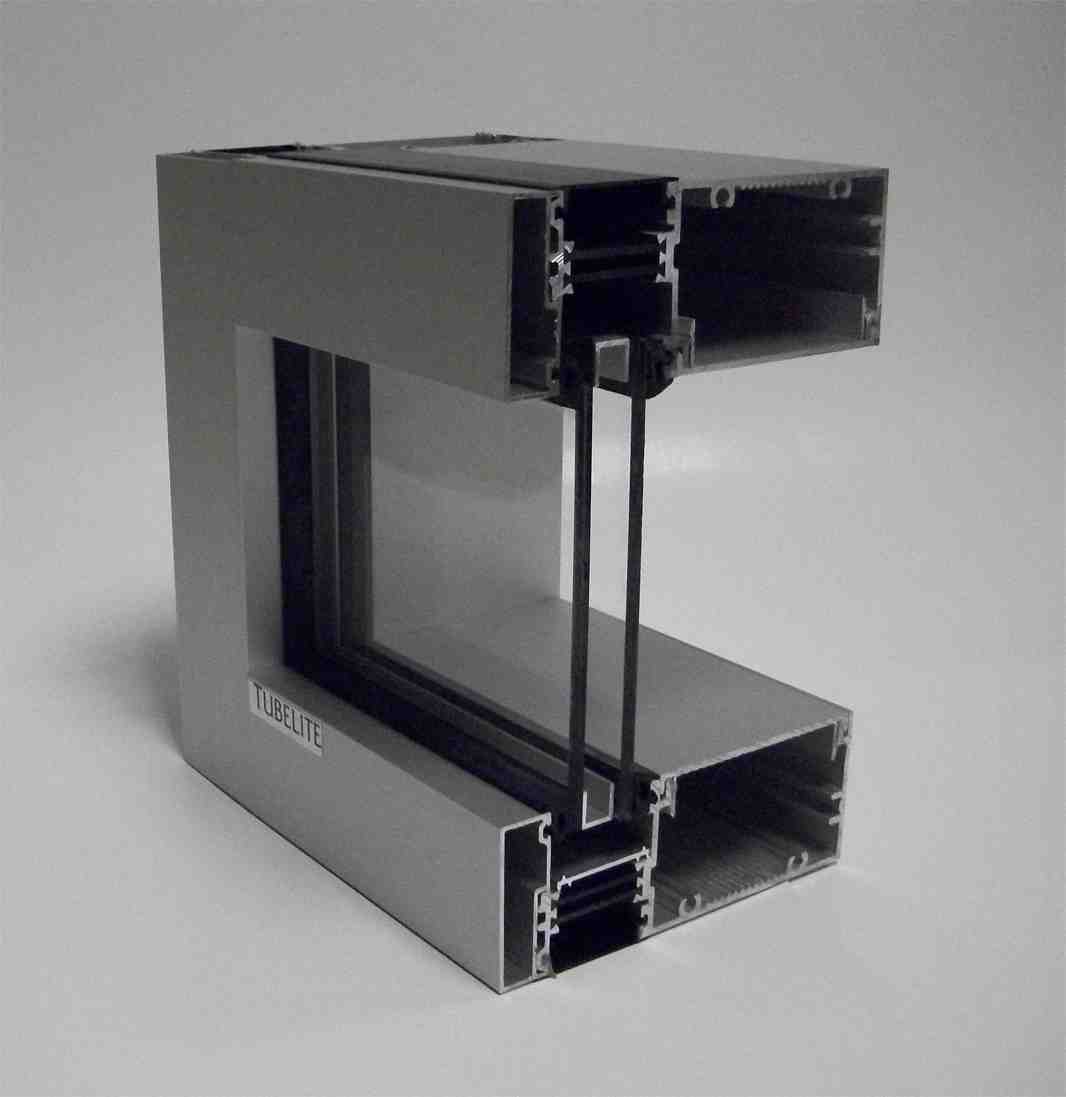

Wausau Window and Wall Systems’ triple-glazed windows are a key feature of the building’s energy-efficient design. The building itself is oriented to optimize natural lighting. The more than 90 project-out, project-in and fixed window units in the school’s design boosted light levels in 90 percent of the classrooms and teaching spaces to at least 25 foot candles of natural light. All of the windows use low-maintenance, between-glass blinds to control light and privacy. Many of the windows used in classrooms are also operable with screens, which allow for natural ventilation.

School principal, Ann Baker, told the Toledo Free Press that the students were in awe of their new space. “They were like ‘wow, windows.'” She also noted, “The building feels healthier and is absolutely environmentally friendly. I think it will increase the children’s learning and brighten their day up.” Numerous studies have shown natural light to benefit students’ health and wellness, morale and attendance, as well as test scores.

Along with academic performance, TPS superintendent John Foley appreciates the thermal performance. “Energy-efficient windows are a staple in the construction of our new schools. The strict standards established by the Ohio School Facilities Commission require the use of energy-efficient windows, especially as we work toward achieving LEED.” He continues, “The windows in our new schools not only provide a safe and healthy learning environment for our students, but the energy-efficient design of the windows saves the district money and energy.”

The need for a combination of energy-efficiency, durability, flexibility and value led Wausau’s regional sales manager Dave DeBettignies and local sales representative Michael Augustine to recommend windows from the Advantage by Wausau product offering. “With the tight timelines, strict budgets, energy goals, and the large number of windows needed for the facilities involved, we knew that the high-performance, standard products offered through Advantage by Wausau would be a perfect value for many of TPS’ new buildings,” says Augustine.

Toledo-based glazing contractor Interstate Commercial Glass & Door, Inc., worked with Wausau on Hawkins Elementary, as well as on several other TPS school buildings. Walt Erickson, vice president and estimator for Interstate, says, “Wausau has been very competitive in their pricing and their lead time. But to me, the number one priority is that Wausau’s quality is top-notch. Their Advantage program takes basic products with top-of-line quality like the 3250 Series windows and offers them with nice lead times and at competitive prices. It’s really been helpful to have speed, cost and quality. You don’t usually get all three.”

Wausau’s 3250 Series windows are proudly backed with up to a 10-year limited warranty, one of longest and most comprehensive in the industry. These project-out, project-in and fixed units feature a polyurethane thermal barrier and are rated as AAMA AW-70 Performance Class. They also are labeled by the National Fenestration Rating Council (NFRC) for energy performance.

Contributing to Hawkins’ energy and other green goals, all Wausau products meet the industry’s most stringent requirements for air infiltration, water resistance and structural integrity. Further enhancing performance and longevity, the 3250 Series windows’ 3.5-inch-deep aluminum frames used in the project were finished by Linetec with a durable, VOC-free, clear anodize finish . The company’s new, eco-friendly, anodize presents a frosty, matte finish that makes it an ideal choice for secondary billet, recycled content.

For Hawkins Elementary, 75 percent of the project’s construction waste was recycled and the final facility contains at least 25 percent recycled materials. Architect Dan Tabor, AIA, with The Collaborative, also notes, “Fifty-one percent of the construction materials used were manufactured within a 500-mile radius, which reduces the school’s carbon footprint.”

The school includes other energy-efficient, cost-effective design strategies, construction methods and building products: An on-site, helix wind turbine generates renewable energy, which directly assists in lighting the lobby and corridors when daylight is not an option. A white reflective roof reflects sunlight, keeping the building cool. An ice storage unit allows the school to utilize ice as part of its cooling system.

Tabor adds, “The building site takes advantage of a rain garden and bioswale to filter storm water, and the school utilizes low-flow water fixtures and waterless urinals, making the water usage 40 percent less than the average school.”

Beyond the operational and environmental benefits of the school, superintendent Foley expressed his hopes that Hawkins Elementary’s green features will serve as a “learning lab for students.”

Download a PDF of the full success story by clicking here and see Wausau’s online Green Building section for more educational facility project examples and resources.

Filed under: AAMA, CLIENT NEWS, Green Goals, Linetec, Wausau Window and Wall Systems | Comments Off on 02.26.10 Client News