04.19.10 Association News

Plumbing Manufacturers Institute volunteers on San Diego Habitat for Humanity project

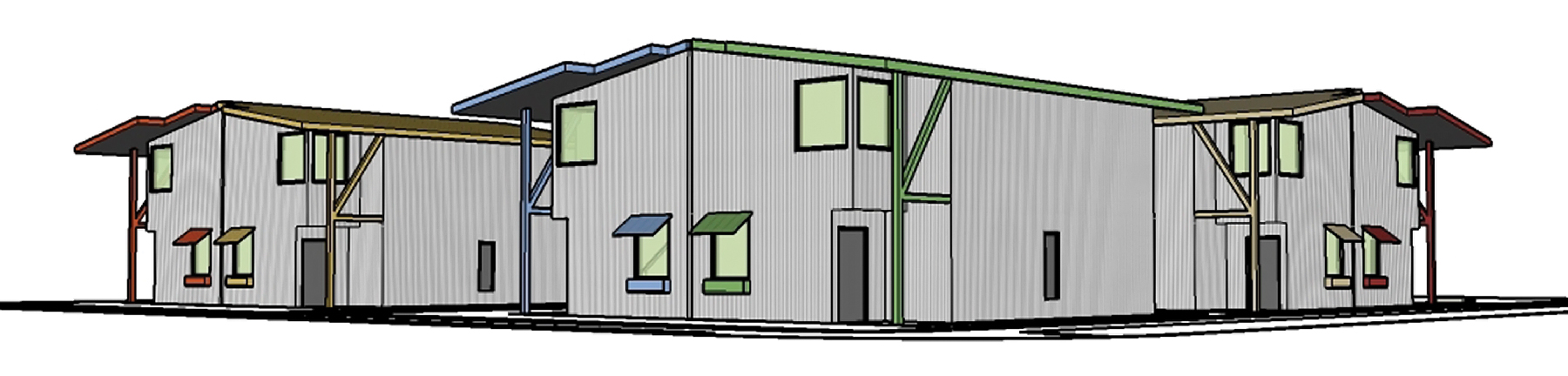

Preceding the Plumbing Manufacturers Institute (PMI) Spring Meeting this March, members and staff volunteered on Habitat for Humanity’s G Avenue project in National City, CA. PMI‘s team assisted with foundation preparation, retaining wall construction, irrigation system installation and other tasks. When completed in 2011, the project will provide eight semi-attached, two-story homes. Each home will have three bedrooms and one-and-a-half baths.

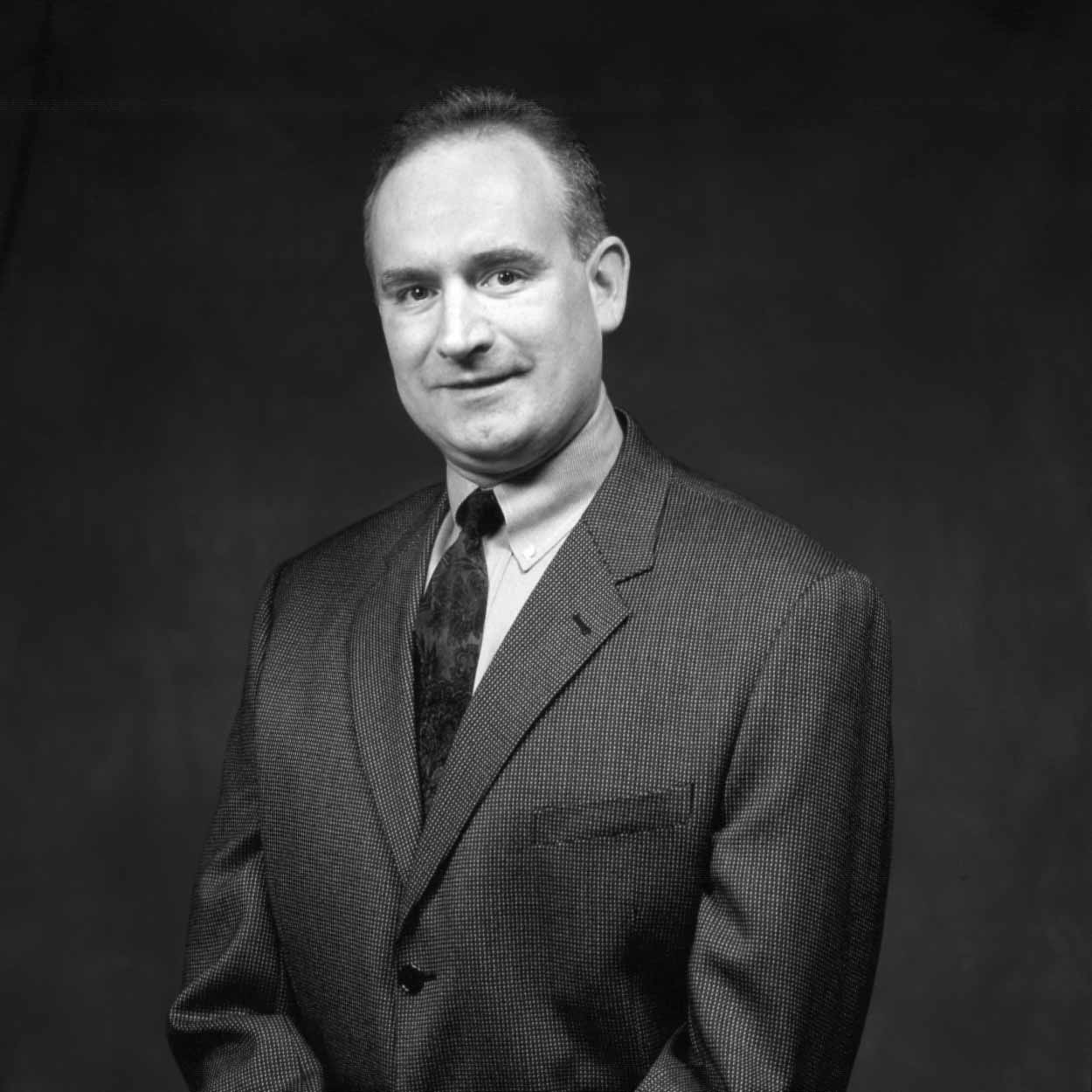

The association’s board president, Lee Mercer, director of product compliance for Moen Incorporated (North Olmsted, OH), led PMI’s Habitat team. “PMI and its members play a critical role in providing safe, clean drinking water and sanitary conditions. This directly and positively contributes to healthy lives and livelihoods for people across the globe,” says Mercer.

He continues, “This is the first year that we’ve included a hands-on opportunity, allowing members to personally contribute their time. It’s a way for us to give back, leave a positive impression and remain connected to the community hosting our meeting. We hope to incorporate similar activities into future meetings.”

Key volunteers on San Diego Habitat for Humanity‘s G Avenue project in National City, included: Barbara C. Higgens, executive director, PMI; David Hagopian, director of strategy and technology, PMI; Peter Jahrling, director of design engineering, Sloan Valve Company (Franklin Park, IL); Sally Remedios, product compliance manager, Delta Faucet Company (Indianapolis, IN); and Matt Dos Remedios, production planner, American Faucet and Coatings Corporation (Vista, CA).

Volunteers received on-site supervision and guidance from John Pulliam, volunteer coordinator, and Joe Carton, site superintendent. Ken Kosman, chief construction officer for the San Diego Habitat for Humanity, offered advance coordination for the PMI team. Kosman spoke at the Spring Meeting, thanking PMI for its volunteers’ efforts and $500.00 donation, and for its members’ ongoing and past donations of plumbing products and materials.

Dedicated to eliminating substandard, poverty housing from its community, the San Diego Habitat for Humanity relies on contributions of land, materials, money and labor to keep building costs low. Partner families invest hundred of hours of their own “sweat equity” and qualify for a zero-interest mortgage that is no more than a third of their income. Mortgage payments are typically less than rental fees charged for inadequate shelter and unsafe living conditions.

“With adequate housing, families can devote more attention to career opportunities, education and health,” according to Kosman. “As the crushing cycle of poverty is broken, children benefit, neighborhoods change for the better, and entire communities improve.”

San Diego Habitat for Humanity has constructed more than 100 homes throughout the county. Learn more at http://www.sdhfh.org/.

For more information about the PMI Spring Meeting, visit http://www.pmihome.org or call 847-481-5500. PMI’s 2010 Fall Meeting will take place October 3-6, 2010, at the Liaison Capitol Hill in Washington, D.C.

For more information about the PMI Spring Meeting, visit http://www.pmihome.org or call 847-481-5500. PMI’s 2010 Fall Meeting will take place October 3-6, 2010, at the Liaison Capitol Hill in Washington, D.C.

Please see the full news release and high-resolution photos available at PMI’s online press room.

Filed under: CLIENT NEWS | Comments Off on 04.19.10 Association News