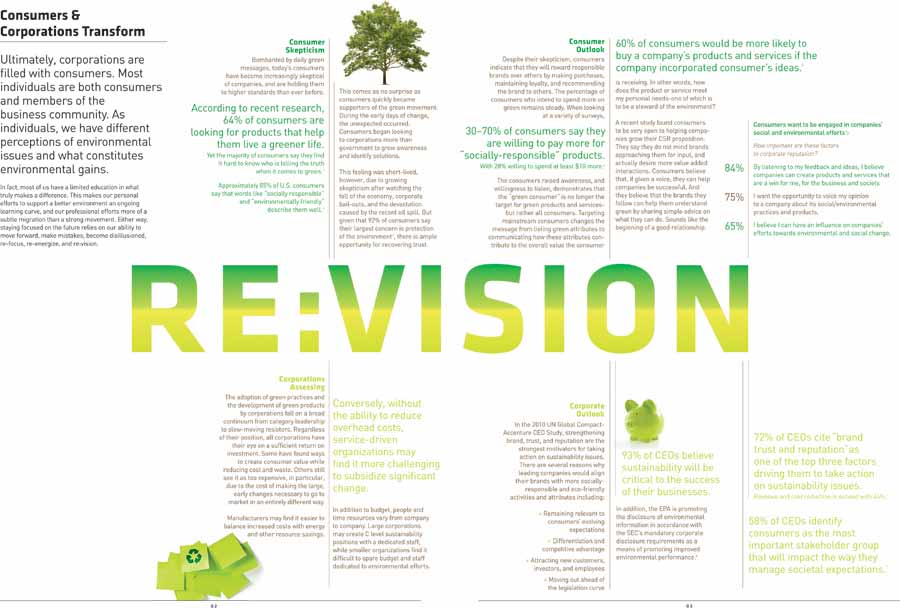

University of Wisconsin at Whitewater’s Starin Hall reaches accessible, sustainable goals with help from Wausau’s windows

photo by Nels Akerlund, provided by Potter Lawson

In July 2010, the University of Wisconsin at Whitewater (UW-Whitewater) opened Starin Hall residence facility for juniors, seniors and graduate students. Its 119 suites boast expansive campus views, daylighting and natural ventilation, courtesy of Wausau Window and Wall Systems.

Wausau’s operable windows contribute to the hall’s energy efficiency, low maintenance, long lifespan and its anticipated Gold certification under the LEED® Green Rating System. If successful in achieving U.S. Green Building Council’s LEED certification, Starin Hall will be the first state-owned, LEED-certified residence hall in the state.

As the first new residence hall to be built on the UW-Whitewater campus in more than 40 years, much thought was given to the building’s design and construction. In lieu of the two separate buildings that Starin Hall replaced, Potter Lawson and design partner Cannon Design envisioned a single residence hall with two distinct north and south wings. J.P. Cullen & Sons; Janesville, Wis., served as the project’s general contractor, helping bring the $33 million project to life.

The resulting, new student residence includes 90 four-person, traditionally-designed suites; 10 Resident Assistant suites; and 19 four-person, “universal design” suites, doubling the number required by the Americans with Disabilities Act. Universal design creates environments that are accessible for all users, regardless of age, mobility, visual, auditory or mental ability.

In addition to creating a welcoming, inclusive environment for students with disabilities, University officials were committed to supporting the “UW Builds Green” initiative. Supporting this initiative, more than 550 projected, high-performance windows were provided by Wausau and installed by glazing contractor B&D Contractors, Inc. Manufactured in Wausau’s own LEED-Silver facility, the operable units feature Low-E glazing to maximize solar energy control for the majority of the suite’s southern exposures.

Along with thermal performance, interior comfort, daylighting and view, building projects

photo by Nels Akerlund, provided by Potter Lawson

seeking LEED certification also may benefit from recycled material content. As part of its Advantage by Wausau product offering, all standard, projected windows now are fabricated using recycled aluminum, while continuing to meet education facilities’ accelerated construction timelines and limited budgets.

The aluminum frames for both Wausau’s 3250 Series and 4250 Series windows are protected with a durable, two-coat, 70% fluropolymer, Sandstone-colored coating, painted by Linetec. Wausau’s finished window units are backed with up to a 10-year warranty for reliable, smooth-operating performance in buildings with high use and extreme climates.

Attaining the project’s environmental and accessibility goals meant taking a highly-collaborative approach. Early in the project’s planning stages, workshops on universal and sustainable design concepts were held on campus. Staff, students and university representatives teamed with project architects at Potter Lawson to establish the high level of accommodation desired in the new residence, as well as a common awareness of green-minded concepts that would be used throughout the building’s design. Students toured new residence halls on two other UW campuses to explore how various environmental design options could support and enrich their campus experience.

The resulting accessible and sustainable design elements are found throughout Starin Hall’s public and private spaces. All 436 residents can monitor their power usage through a touch-screen kiosk in the lobby area. Each energy-efficient suite includes four single-occupancy, 9-by-12-foot bedrooms; a common area, kitchenette and bathroom.

Students with disabilities will find multi-gender bathrooms to accommodate caregivers, roll-in showers with stools, as well as lowered service desks, two elevator banks, and hallways and doorways suitable to handle their wheelchairs. Other building amenities include office and support facilities, a front desk/main lounge area, a faculty office, two collaborative learning rooms, a dividable seminar room, a computer lab, game rooms and a multi-purpose basement. The basement common spaces and ground floor join Starin Hall’s two residential wings, as does a glass-enclosed bridge on the upper floors.

An external courtyard between the two wings includes a walking path and a small gathering space at the courtyard’s west end. The crushed limestone used for walking path’s base reduces the environmental impact of impervious surfaces, but still allows universal access. Several student entrances to the hall are level with an adjacent residence parking lot. The 50-stall parking lot offers eight parking stalls marked as handicapped accessible. The parking area also contains a trash/recycling enclosure and covered bike stalls.

photo by Nels Akerlund, provided by Potter Lawson

The site’s location preserved existing green space. The new landscaping includes deciduous trees, lawn areas, and low shrubs. No irrigation was included in the project, so plants were selected for drought tolerance, high disease resistance, and low maintenance.

Of the 1,134 students who applied to live in Starin Hall, less than one-third gained acceptance for the 2010-11 school year. All of those on UW’s campus can be proud to add the new residential hall to the university’s long list of accomplishments: national-champion football and wheelchair basketball teams, a place in history as Wisconsin’s second public college, a commitment to accommodating students with disabilities and a dedication to creating a sustainable, environmentally-friendly campus.

**

Starin Hall, University of Wisconsin – Whitewater, Whitewater, Wis.

Owner: University of Wisconsin

Architect: Potter Lawson, Inc.; Madison, Wis.,

in partnership with Cannon Design; Chicago

Contractor: J.P. Cullen & Sons; Janesville, Wis.

Glazing contractor: B&D Contractors, Inc.; New Berlin, Wis.

Glazing systems – manufacturer: Wausau Window and Wall Systems; 4250 Series and 3250 Series windows; Wausau, Wis.

Glazing systems – finisher: Linetec; Wausau, Wis.

Filed under: Buildings + Infrastructure, CLIENT NEWS, Green Goals, Linetec, Projects, USGBC, Wausau Window and Wall Systems | Comments Off on 11.30.10 Client News