Building on a successful 2010 effort to help the U.S. Department of Energy (DOE) create the “greenest office building” in the nation, Wausau Window and Wall Systems returned to contribute to the National Renewable Energy Laboratory’s (NREL’s) Research Support Facility (RSF) planned expansion. For RSF’s expansion, Wausau provided its highest performing triple-glazed windows and custom curtainwall, and assisted the design/build team in improving upon the initial structure’s exceptional energy performance.

successful 2010 effort to help the U.S. Department of Energy (DOE) create the “greenest office building” in the nation, Wausau Window and Wall Systems returned to contribute to the National Renewable Energy Laboratory’s (NREL’s) Research Support Facility (RSF) planned expansion. For RSF’s expansion, Wausau provided its highest performing triple-glazed windows and custom curtainwall, and assisted the design/build team in improving upon the initial structure’s exceptional energy performance.

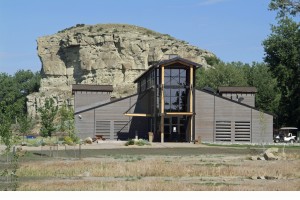

Completed in November 2011, the RSF expansion’s occupants finished moving into their new Class A offices at the end of February 2012. In all campus development, NREL serves as a “living laboratory” integrating energy efficiency and renewable energy, high-performance buildings and sustainable transportation. At NREL’s 327-acre South Table Mountain Campus near Golden, Colo., NREL’s RSF is designed and built to attain U.S. Green Building Council’s LEED® Platinum certification.

Unlike typical office buildings, NREL’s RSF is designed to be a carbon-neutral, net-zero energy building, developed to produce as much power as it consumes. For the RSF expansion, the design/build team of Haselden Construction and RNL’s Denver area architects were challenged to achieve a 17% savings in overall energy performance compared with the highly efficient first phase of RSF.

Funding to build the second phase of RSF came through the American Recovery and Reinvestment Act as a “shovel-ready” project. Along with ongoing energy savings, upfront financial savings were emphasized during construction of the 138,000-square-foot RSF expansion. Construction costs for the RSF expansion were $264/square foot, compared to $335/square foot for the cost of a typical newly constructed commercial building designed to achieve LEED certification. Calculated as a whole, the total construction costs for RSF’s 360,000-square-foot ultra-high-performance structures were $254/square foot with total energy use of only 34.4 kBtu/sf/yr. Together, RSF supports a combined building occupancy of more than 1,325 people.

Funding to build the second phase of RSF came through the American Recovery and Reinvestment Act as a “shovel-ready” project. Along with ongoing energy savings, upfront financial savings were emphasized during construction of the 138,000-square-foot RSF expansion. Construction costs for the RSF expansion were $264/square foot, compared to $335/square foot for the cost of a typical newly constructed commercial building designed to achieve LEED certification. Calculated as a whole, the total construction costs for RSF’s 360,000-square-foot ultra-high-performance structures were $254/square foot with total energy use of only 34.4 kBtu/sf/yr. Together, RSF supports a combined building occupancy of more than 1,325 people.

Keeping building occupants comfortable, the four-story RSF expansion features a 60-foot wide office space that allows for deep penetration of natural daylight and cross ventilation – primary drivers in visual and thermal comfort, as well as in energy conservation. Wausau worked closely with glazing contractor J.R. Butler, Inc., to incorporate innovative approaches to optimize visible light and views, to provide natural ventilation and control unwanted heat gain, while managing the abundant natural daylight.

More than 450 bays were installed on the RSF expansion using Wausau’s triple-glazed 2250i XLT Series INvent™ fixed and projected windows. In addition to the window bays, Wausau provided J.R. Butler with 4,600 square feet of custom curtainwall and accessories.

J.R. Butler worked directly with Rocky Mountain Prestress and installed the windows into concrete exterior wall units. These units were pre-fabricated and assembled in Rocky Mountain Prestress’ factory and then crane-lifted into place on RSF’s job site. “This unitized approach offered tremendous time savings and cost savings, as well as ensured the proper performance,” explains Wausau’s Colorado-based representative, Cynthia Workman-Snow.

J.R. Butler worked directly with Rocky Mountain Prestress and installed the windows into concrete exterior wall units. These units were pre-fabricated and assembled in Rocky Mountain Prestress’ factory and then crane-lifted into place on RSF’s job site. “This unitized approach offered tremendous time savings and cost savings, as well as ensured the proper performance,” explains Wausau’s Colorado-based representative, Cynthia Workman-Snow.

“In response to increased stringency of Model Energy Codes, as well as net zero energy buildings and carbon neutral sustainability goals, many Wausau products are designed to accept triple glazing for buildings of the future,” says Wausau’s government market manager and senior design engineer, Tom Mifflin, LEED Green Associate. “More than 25 years of triple-glazed product development gives us a unique, ‘no problem’ perspective on energy-saving technology.”

Like the first phase of RSF, every workstation in the expansion has 100% daylighting and no workstation is more than 30-feet from an operable window. The operable window units can be opened automatically and manually. “The profile of the RSF expansion matches that of the first phase, but it is designed with more significant thermal constraints and a new window and curtainwall system,” explains Russell Williams, project manager with J.R. Butler.

To meet the challenge, Wausau provided 2250i XLT Series INvent windows with recycled aluminum framing, extra-wide polyamide thermal barriers supplied by Linetec, and triple insulating glass supplied by Viracon. The combination of these high-performance components, experienced engineering and quality fabrication allow the windows to achieve NFRC U-Factors as low as 0.19, equivalent to R5.3. Condensation Resistance Factors range from 59 to 68.

To meet the challenge, Wausau provided 2250i XLT Series INvent windows with recycled aluminum framing, extra-wide polyamide thermal barriers supplied by Linetec, and triple insulating glass supplied by Viracon. The combination of these high-performance components, experienced engineering and quality fabrication allow the windows to achieve NFRC U-Factors as low as 0.19, equivalent to R5.3. Condensation Resistance Factors range from 59 to 68.

Validating the windows’ performance, INvent Series’ products are tested to meet AAMA AW-100 Architectural Performance Class ratings, including new AAMA 910-10 lifecycle testing to 4000 operating cycles and stringent requirements for air infiltration, water resistance, thermal cycling and structural integrity.

“Wausau’s AW Class hardware carries the added weight of triple glazing with ease,” adds Kevin Robbins, Wausau’s regional sales manager. “INvent windows offer the low required U-Factors without compromising reliable operation, aesthetics or durability.”

Matching the look of RSF’s first phase and enhancing the products’ durability, Linetec also finished all of the recycled aluminum framing material for the RSF expansion in a silver-hued mica, polyvinylidene fluoride coating. The durable finish presents an eye-catching, metallic shimmer that withstands the exterior elements. The liquid coating is applied in Linetec’s factory using specialized equipment to safely capture 100% of the volatile organic compounds (VOCs) released in the painting process, and to use these captured VOCs as an energy-efficient, environmentally sensitive process input.

Along with th e window systems’ durable finishes, recycled content and high thermal performance, many of the sustainable features used in the original structure have been further enhanced due to technological advances. These include:

e window systems’ durable finishes, recycled content and high thermal performance, many of the sustainable features used in the original structure have been further enhanced due to technological advances. These include:

* Improved efficiency of rooftop photovoltaic panels

* Improved lighting control systems

* Increased flexibility in mechanical systems integration

“If we can inspire the industry to achieve higher energy performance with new builds or retrofits, then we’ve met our challenge with this project,” said Haselden’s president, Byron Haselden.

NREL has committed to DOE’s goal of achieving LEED Gold or Platinum certification for all new construction and to exceed American Society of Heating Refrigerating and Air-Conditioning Engineers (ASHRAE) 90.1-2004’s requirements. RSF is anticipated to be 50% more energy efficient than the ASHRAE baseline building performance. NREL also upholds the new Better Buildings Initiative to make commercial and industrial buildings 20% more energy efficient by 2020 and accelerate private sector investment in energy efficiency.

Construction of NREL’s new high-performance buildings and renewable energy systems take advantage of alternative financing mechanisms, including power purchase agreements (PPA), energy savings performance contracts (ESPC), partnerships with energy service companies (ESCO), and cooperative research and development agreements (CRADA). NREL also continues to review the use of overhead funds, cost savings reinvestment, and leveraging of alternative finance for retrofits or new projects.

**

National Renewable Energy Laboratory’s Research Support Facility expansion,

South Table Mountain Campus, Colo.; http://www.nrel.gov

* Owner: U.S. Department of Energy; Washington, D.C.; http://www.doe.gov

* Architect: RNL; Denver; http://www.rnldesign.com/markets/government//nrel/#

* General Contractor: Haselden Construction LLC; Centennial, Colo.; http://www.haselden.com

* Glazing contractor: J.R. Butler, Inc.; Denver; http://www.jrbutlerinc.com

* Glazing systems – manufacturer: Wausau Window and Wall Systems; Wausau, Wis.; http://www.wausauwindow.com

* Glazing systems – glass assemblies: Viracon, Inc.; Owatonna, Minn.; http://www.viracon.com/

* Glazing systems – finisher: Linetec, Wausau, Wis.; http://www.linetec.com

* Photos by: DOE/NREL, Dennis Schroeder, http://www.nrel.gov/news/rsfnews/photos.html

###

Filed under: AAMA, Buildings + Infrastructure, CLIENT NEWS, CSI, Green Goals, Linetec, Projects, USGBC, Wausau Window and Wall Systems | Comments Off on Wausau triple-glazed INvent windows support net-zero energy and LEED Platinum goals for NREL RSF expansion