Sustainability, functionality and enduring architectural presence interweave to define three new University of Delaware (UD) projects. Wausau Window and Wall Systems manufactured a variety of high-performance curtainwall, windows and sun shades to meet the performance requirements and aesthetic vision for each project.

* Interdisciplinary Science and Engineering Laboratory – The new 194,000-square-foot facility was designed by Baltimore-based architects Ayers Saint Gross (ASG). Whiting-Turner Contracting Company began construction on the $140 million project in Autumn 2010 and is scheduled for completion in Autumn 2013.

* East Campus Utility Plant – Also designed by ASG and guided by Whiting-Turner, the building supports the increased load demands associated with several new UD building projects, including the ISE Lab. The $37.5 million, 25,000-square-foot facility was completed in Autumn 2010.

* Bob Carpenter Convocation/Sports Center – Designed by HNTB, the 54,000-square-foot expansion includes new practice facilities for the men and women’s basketball teams and the women’s volleyball team. Whiting-Turner Contracting completed the $32 million addition in October 2011.

These projects are part of UD’s 10-year initiative to construct and upgrade facilities to offer its students the best in advanced technology and space.

Interdisciplinary Science and Engineering Laboratory

The new Interdisciplinary Science and Engineering Laboratory (ISE Lab) heads the list of UD’s major building initiatives. As with many new construction initiatives, environmental responsibility was essential in the University’s physical and operational plans. In compliance with UD’s Science and Technology Campus Master Plan, the ISE Lab was designed to meet the U.S. Green Building Council’s (USGBC’s) LEED® Gold certification criteria.

The new Interdisciplinary Science and Engineering Laboratory (ISE Lab) heads the list of UD’s major building initiatives. As with many new construction initiatives, environmental responsibility was essential in the University’s physical and operational plans. In compliance with UD’s Science and Technology Campus Master Plan, the ISE Lab was designed to meet the U.S. Green Building Council’s (USGBC’s) LEED® Gold certification criteria.

Wausau Window and Wall Systems’ energy-efficient windows and recycled aluminum framing contribute toward meeting the LEED goal. Students, staff and visitors to the ISE lab will have ample daylight and views of the surrounding campus and community thanks to AGS’ generous use of windows and glass in the building’s design. The high-performance, reflective glass façade complements the lobby’s sleek, modern design aesthetic.

The building’s L-shaped layout features an expansive two-story lobby that will serve as the principal access point to the new ISE Lab. The lobby’s design offers an impressive gathering space for students, faculty, visiting scholars, corporate partners and alumni. The two floors above the lobby host multiple “learning suites” that form the core of the ISE Lab’s instructional space. Each teaching space contains a centralized classroom, two laboratories and smaller “prep” rooms.

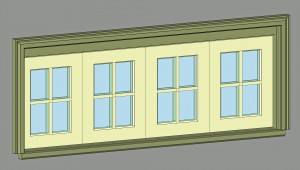

Glazing contractor R.A. Kennedy & Sons of Ralston, Pa. specified and installed 20,000 square feet of Wausau’s curtainwall for the ISE Lab’s entrance and 345 fixed casement windows throughout the facility. Wausau provided its 3250iV and 4250iV Series Visuline™ windows with polyamide thermal barriers supplied by Linetec, and glass fabricated by Viracon. The combination of these high-performance components, experienced engineering and quality fabrication allow the windows to achieve NFRC U-Factors as low as 0.39 and a Condensation Resistance Factors (CRF) range from 54 to 62. The windows’ acoustic performance is tested for Sound Transmission Class (STC) ratings of 33 to 48.

Validating the windows’ performance, Visuline products are tested to meet AAMA AW-100 Architectural Performance Class ratings, including AAMA 910-93 lifecycle testing to 2500 operating cycles and stringent requirements for air infiltration, water resistance, and structural integrity.

In addition to the Visuline windows, Wausau also engineered and factory-fabricated its 6750 and 8750 SG Series four-side silicone-glazed curtainwall in 6.75- and 8.75-inch frame depths. Similar to the high-performance windows, the SG Series curtainwall can achieve NFRC U-Factors as low as 0.37 BTU/hr.sqft.ºF, which allow for broad expanses of Viracon’s vision glass. The curtainwall grid frames were factory-fabricated and shipped to R.A. Kennedy for field assembly at the jobsite.

Prior to shipping, Linetec finished the window and curtainwall systems’ aluminum framing in a Silver Gray. This custom color uses a three-coat Fluropon® Classic II 70% polyvinylidene fluoride (PVDF) mica coating. In addition, a clear anodize was used. “These are some of the most durable coatings available,” says Linetec’s senior marketing specialist, Tammy Schroeder, LEED Green Associate. “Their long lifecycle reduces the need for maintenance and replacement and minimizes the associated time, cost and materials.”

As an environmentally responsible finisher, Linetec safely captures and destroys the liquid paints’ volatile organic compounds (VOC) content before the finished material arrives at the job site. For projects like ISE Lab that seek LEED certification, choosing durable products with no-VOC finishes can be an important part of the selection and specification process.

Beyond the window systems’ durable finishes, recycled content and high thermal performance, ISE Lab’s additional sustainable design features and energy-efficient practices include:

* motors with variable frequency drives that control energy use based on demand and occupancy,

* proximity sensors that power off equipment and lights when laboratories are empty,

* a vegetative, green roof, and

* photovoltaic cells to convert sunlight to electricity.

UD’s Institute of Energy Conversion is a national leader in wind and solar power, photovoltaic energy cells, power grid connectivity and bio-fuels. The new facility will support that important work with an imaging and microscopy suite, a 10,000-square-foot nano-processing clean room, a synthesis lab for chemical research, a materials characterization lab and workspace.

“Construction on our campus is closely tied to our strategic plan, dubbed the ‘Path to Prominence,’ focusing on our commitment to our students and the world,” said David Singleton, vice president of facilities and auxiliary services. “The ISE lab furthers that progress by creating spaces for teaching, learning and research to come together in an integrated way.”

Additionally, Singleton noted that it was important that energy- efficient, environmentally responsible products be used in the school’s building projects as much as possible. “The University of Delaware has a strong history of environmental research and education. It’s not just something we teach; it’s something we live. Thus, it is important to us that we optimize the energy efficiency of our campus buildings.”

East Campus Utility Plant Project

For UD’s East Campus Utility Plant Project, glazing contractor R.A. Kennedy & Sons again called on Wausau for high-performance, window and wall systems.

“We found Wausau’s approach of interacting as part of the construction team, not just maintaining a typical customer/supplier relationship, to be a key component of the project’s success,” said R.A. Kennedy & Sons’ director of sales, Jerry Moser. “That, together with Wausau’s project management team asking all the right questions and coordinating a difficult project with a plethora of different façade interfaces, more than proved they were the right partner for the University of Delaware projects.”

The three-level utility building houses a pair of 2,750-ton chillers, a new electrical substation and cooling towers, and is large enough to accommodate additional chillers in the future. The building’s brick, slate and metal panels harmonize with the existing architecture on campus and the new ISE Lab. However, the plant’s proximity to the nearby Russell student housing complex meant acoustic performance was an integral part of the facility’s design and construction.

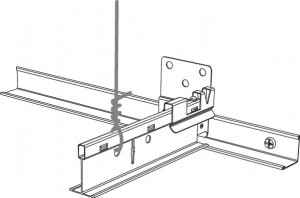

Addressing the acoustical and thermal performance, Wausau responded with its 4250 Series projected windows and HP-Wall. “HP-Wall provides noise reduction and best-in-class thermal performance. This system contributes to occupant comfort and quieter spaces. It also helps lower operating costs and reduce necessary HVAC capacity, provides exceptional condensation resistance for high humidity applications, and minimizes maintenance costs,” says Steve Gille, Wausau’s education market manager.

Similar to ISE Lab, the aluminum framing for the East Campus Utility Plant was finished by Linetec in three-coat 70 percent PVDF coating in a custom silver gray Fluropon Classic II mica and a Silverstorm Duranar® Sunstorm mica.

Bob Carpenter Convocation/Sports Center

Known by UD as “The Bob,” Wausau curtainwall and ClearStory™ sun shades were used to ensure the exterior of the convocation and sports center’s new two-story addition design complemented the original building. Wausau’s SuperWall™ system two-sided structural glazing and 90-degree corners. Glazing contractor Zephyr Aluminum of Wilmington, Del., installed the 8,000 square feet of curtainwall systems plus sun shades.

Known by UD as “The Bob,” Wausau curtainwall and ClearStory™ sun shades were used to ensure the exterior of the convocation and sports center’s new two-story addition design complemented the original building. Wausau’s SuperWall™ system two-sided structural glazing and 90-degree corners. Glazing contractor Zephyr Aluminum of Wilmington, Del., installed the 8,000 square feet of curtainwall systems plus sun shades.

Exterior sun shades intercept unwanted solar heat gain before it can impact a building’s HVAC system’s load. Sun shades also can economize natural light by redirecting it inside the building. “Lighting accounts for 40% of the energy used in a typical commercial building. Properly executed, daylighting can reduce HVAC peak loads with corresponding reductions in mechanical equipment capacity and carbon footprint,” notes Gille. In climates like Delaware where snow and ice loads may be heavy, he also advises that engineers pay particular attention to the connections between sun shades or outriggers and the curtainwall mullion profiles.

For The Bob, Wausau’s sun shades, framing and accent aluminum were finished by Linetec in a clear anodize. This finish meets the AAMA 611-98 specification, which anodize finishes to meet rigorous testing performance standards including 3,000 hours of salt spray resistance. Linetec’s Schroeder notes its other benefits: “Unlike other finishes, as an integral part of the substrate, anodizing highlights aluminum’s metallic appearance. Anodized aluminum is 100% recyclable, contains no VOCs, and resists the ravages of ultraviolet radiation, temperature, corrosion, humidity and warping — adding to its long life-cycle.”

The Bob’s expansion is part of the David M. Nelson Athletic Complex, which includes 23,000-seat Delaware Stadium, the Delaware Field House, the 2,000-seat Delaware Diamond, numerous athletic fields, the Delaware Ice Skating Science Development Center at the Rust Ice Arena, and an outdoor swimming pool. Originally opened in 1992, it is named in honor of the late R.R.M. “Bob” Carpenter Jr., a longtime UD board trustee member, athletic benefactor and former Philadelphia Phillies’ owner.

**

Interdisciplinary Science and Engineering Laboratory

* Owner: University of Delaware; Newark, Del.

* Architect: Ayers Saint Gross; Baltimore, Md.

* General contractor: Whiting-Turner Contracting Company; Newark, Del.

* Glazing contractor: R. A. Kennedy & Sons; Ralston, Pa.

* Glazing systems – manufacturer: Wausau Window and Wall Systems’ 6750 and 8750-SG curtainwall and 3250iV and 4250iV Visuline windows; Wausau, Wis.

* Glazing systems – glass: Viracon; Owatonna, Minn.

* Glazing systems – finisher: Linetec; Wausau, Wis.

East Campus Utility Plant

* Owner: University of Delaware; Newark, Del.

* Architect: Ayers Saint Gross; Baltimore, Md.

* General contractor: Whiting-Turner Contracting Company; Newark, Del.

* Glazing contractor: R. A. Kennedy & Sons; Ralston, Pa.

* Glazing systems – manufacturer: Wausau Window and Wall Systems’ HP-Wall and 4250 Series projected windows; Wausau, Wis.

* Glazing systems – finisher: Linetec; Wausau, Wis.

Bob Carpenter Convocation/Sports Center

* Owner: University of Delaware; Newark, Del.

* Architect: HNTB; Kansas City, Mo.

* General contractor: Whiting-Turner Contracting Company; Newark, Del.

* Glazing contractor: Zephyr Aluminum; Wilmington, Del.

* Glazing systems – manufacturer: Wausau Window and Wall Systems’ U-Wall, SuperWall and ClearStory Sun Shades; Wausau

* Glazing systems – glass: Guardian Industries; Auburn Hills, Mich.

* Glazing systems – finisher: Linetec; Wausau, Wis.

Photos by Evan Krape, University of Delaware

###

Filed under: AAMA, ALL TOPICS, Buildings + Infrastructure, CLIENT NEWS, Green Goals, Linetec, Projects, USGBC, Wausau Window and Wall Systems | Comments Off on Client news: Three University of Delaware rely on Wausau window systems; part of Master Plan to meet technology, sustainability and growth goals

Growing its collection of more than 3,000 window and door models and building information modeling (BIM) tools, Kolbe has added new Google™ SketchUp and Revit® 3-D models of its Ultra Series Folding Window.

Growing its collection of more than 3,000 window and door models and building information modeling (BIM) tools, Kolbe has added new Google™ SketchUp and Revit® 3-D models of its Ultra Series Folding Window.