Client News: Technoform Bautec’s thermal barrier system helps Houghton Academy’s new windows match historic aesthetic

Technoform Bautec North America, Inc., contributes to the updated appearance and enhanced performance of historic Houghton Academy in Buffalo, N.Y. Along with refreshed façade, the elementary school’s modern windows feature Technoform Bautec’s polyamide thermal barrier for energy efficiency, structural performance and long-term durability.

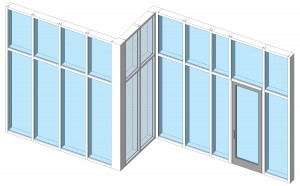

Glazing contractor T.G.R. Enterprises replaced 125 of the building’s outdated windows with Wausau Window and Wall Systems’ high-performance units. These windows were finished by Linetec and customized to match the elementary school’s architectural aesthetic using a Sandstone color paint on the exterior and a Dark Bronze anodize on the interior.

Constructed in 1924, Buffalo Public School #69 Houghton Academy was designed by the Associated Buffalo Architects Inc. The U-shaped floor plan surrounds a courtyard in the rear and a Classic Revival style entrance in the front. The brick and stone structure is punctuated with large window bays. As time passed, the windows were replaced without preserving the architectural integrity. This resulted in inconsistent window types, trim and colors.

“Choosing different color schemes and finish types for the interior and exterior of a high-performance aluminum window system can be achieved within budget and on accelerated timelines,” says Chad Ricker with Technoform Bautec’s market team. “Because two different finishing types were used on Houghton Academy windows — paint and anodize, any other thermal barrier method would not have been an option for this project.”

To ensure a successful result, the glazing team relied on Wausau’s 310i Series single-hung and 4250i-XLT INvent™ Series project-out windows. Both are manufactured using Technoform Bautec’s polyamide thermal barriers, known generically as “thermal strip.”

For two-color frame finishing using paint at the interior and exterior, Linetec estimates that Technoform Bautec’s thermal strip system painted assemblies are 400% less expensive than other thermal barrier methods that require time-consuming masking.

In addition to cost savings, Houghton Academy’s windows’ Sandstone paint color matches the stonework surrounding them. Christine Hentz, architect with the Buffalo Board of Education, explains, “I selected a color that matched the limestone. On the interior, we maintained the original wood frame, trim and sills. The woodwork is finished in this brownish olive color that is very specific to our schools. It’s practically impossible to match, so we went with a Dark Bronze on the windows’ interior finish that looks nice.”

Wausau’s custom-contoured panning profile helped replicate the look of the windows’ original profile. The majority of windows also feature glazed-in grid muntins with beveled profiles to accentuate the classic appearance. Linetec painted the panning, muntins and windows’ exteriors in the Sandstone color using a 70% Polyvinylidene Fluoride (PVDF) two-coat, in-house blend.

“Seventy percent PVDF coatings offer the ultimate protection in building performance. These are some of the most durable coatings available. Their long lifecycle reduces the need for maintenance and replacement and minimizes the associated time, cost and materials,” says Linetec’s senior marketing specialist, Tammy Schroeder, LEED® Green Associate.

“Seventy percent PVDF coatings offer the ultimate protection in building performance. These are some of the most durable coatings available. Their long lifecycle reduces the need for maintenance and replacement and minimizes the associated time, cost and materials,” says Linetec’s senior marketing specialist, Tammy Schroeder, LEED® Green Associate.

She continues, “The Dark Bronze not only is a different color, but also an entirely different finish process. Because it is an integral part of the substrate, anodize highlights aluminum’s natural beauty and metallic appearance. The anodic coating results in a hard, durable substance providing excellent wear and abrasion resistance with minimal maintenance.”

Because interior and exterior components can be finished at Linetec before assembly of the thermal strip system, dual-color designs, or even dual-finishes, can be achieved easily and efficiently. With other thermal improvement systems, dual-color, or “two-tone,” finishing involves painting one side of the material one color; then masking it off and painting the other side a different color.

“When the building design calls for different interior and exterior finishes, thermal strip becomes the most economical option,” says Schroeder. “When a two-tone anodize is specified – or a paint and anodize interior/exterior, like this project – it is practically impossible to accomplish with anything other than thermal strip.”

Technoform Bautec’s polyamide composition “creates a highly effective thermal barrier that helps insulate approximately 500 times better than aluminum,” explains Phil Effler, part of Technoform Bautec’s north-central sales and market team. “Because it expands and contracts at a rate similar to aluminum, Technoform Bautec’s system delivers long-term durability and water-tightness in a properly assembled profile. It also resists heat distortion and withstands most chemicals used in the construction industry.”

He continues, “Using Technoform Bautec thermal strip for aluminum separation lowers conductivity, thereby reducing the windows’ thermal transmittance (U-Factor), while increasing condensation resistance. Low U-Factors allow broad expanses of vision glass to meet Model Energy Codes.” Enhancing thermal performance for Houghton Academy, the windows are factory-glazed at Wausau’s manufacturing center using Viracon‘s VE1-85 insulating glass.

Simulating the look of double-hung windows, Wausau’s 4250i-XLT INvent project-out windows are easier to operate and have no counter-balancing mechanisms to maintain or replace. “When you have a double-hung with full divided lites and insulated glass in these large sizes, they tend to be very, very heavy. Wausau offered a unit that appears to be a double-hung, but is fixed on top and swings out on the bottom,” says Hentz. “Now, teachers can easily open and close the windows.” Taking effortless operation to the next level, Wausau also prepared the gymnasium’s replacement clerestory windows for motorized operation.

In November 2012, T.G.R. Enterprises completed the three-month window replacement project. Working after school hours to avoid disrupting students and faculty, the team achieved a unified look with improved performance.

Today, Buffalo Public School #69 Houghton Academy serves more than 500 pre-kindergarten through 8th grade students, faculty and staff. It is one of 65 facilities in a district of 37,000 students.

“Ultimately no one can deny the success of this reconstruction and historic preservation program. The district realizes that strong, successful schools are vital for the city to thrive. In addition, these facilities are the focal points within their neighborhoods and can be the catalyst for community redevelopment,” noted Buffalo Public School’s director of facilities, planning, design and construction, Paul McDonnell, AIA, in a column for Buffalo Rising.

McDonnell also is former president of the Buffalo/Western New York chapter of the American Institute of Architects (AIA), president of the Campaign for Greater Buffalo History, Architecture and Culture and chairperson of the Buffalo Preservation Board. He concluded, “Buffalo has been able to maintain the integrity of its architecturally significant schools while creating learning environments that are a match to any other in New York State.”

**

Buffalo Public School #69 Houghton Academy, 1725 Clinton St. Buffalo, N.Y. 14206; http://www.buffaloschools.org/HoughtonAcademy.cfm

* Owner: Buffalo Public Schools; Buffalo, N.Y.; http://www.buffaloschools.org/

* Architect: Buffalo Board of Education; Buffalo, N.Y.; http://www.buffaloschools.org/district.cfm?subpage=73

* General and glazing contractor: T.G.R. Enterprises, Inc.; Buffalo, N.Y.

* Glazing systems – manufacturer: Wausau Window and Wall Systems; Wausau, Wis.; http://www.wausauwindow.com

* Glazing systems – glass fabricator: Viracon, Inc.; Owatonna, Minn.; http://www.viracon.com/

* Glazing systems – finisher: Linetec, Wausau, Wis.; http://www.linetec.com

* Glazing systems – thermal barrier system: Technoform Bautec North America Inc.; Twinsburg, Ohio; http://www.technoform-bautec.us

* Photos by: Orchard Photography

###

Filed under: AIA, CLIENT NEWS, Linetec, Products, Projects, Technoform Bautec, Wausau Window and Wall Systems | Comments Off on Client News: Technoform Bautec’s thermal barrier system helps Houghton Academy’s new windows match historic aesthetic