Client News: Deloitte Tower, first LEED Platinum-certified office building in Montreal, features energy-efficient glazing and TGI-Spacers

Posted on April 14th, 2017 by TGI

Deloitte Tower/La Tour Deloitte is the first office tower in Montreal to be certified LEED® Platinum by the Canadian Green Building Council (CaGBC). The 22-story 560,000-square-foot facility's achievement was announced in July 2016 and credited in part to the energy-efficient curtain wall vision glass and spandrel panels that feature insulating glass units (IGUs) fabricated by Multiver and Technoform Glass Insulation's TGI®-Spacers.

Deloitte Tower/La Tour Deloitte is the first office tower in Montreal to be certified LEED® Platinum by the Canadian Green Building Council (CaGBC). The 22-story 560,000-square-foot facility's achievement was announced in July 2016 and credited in part to the energy-efficient curtain wall vision glass and spandrel panels that feature insulating glass units (IGUs) fabricated by Multiver and Technoform Glass Insulation's TGI®-Spacers.

Building owner The Cadillac Fairview Corporation Limited said that earning this Platinum certification will reduce the building's energy consumption by up to 40 percent, and its sustainability measures will help tenants reduce employee absenteeism and increase productivity, while providing a more comfortable indoor environment.

The Setting – Downtown Montreal

Cadillac Fairview, along with its major tenant Deloitte, helped create the first, new, privately owned and privately financed commercial office tower in more than 20 years to be built in the city of Montreal. This marks the first step in a $2 billion multi-year plan to develop a prime sector of downtown Montreal creating a vibrant new neighborhood known as Quad Windsor. The tower is located next to the heritage-designated Windsor Station entertainment venue and connects directly to the Bell Centre, home of the Montreal Canadiens professional hockey team.

The Challenge – Aggressive Green Building Performance

Cadillac Fairview initiated a nationwide effort known as "Green at Work." This program tracks energy consumption, water usage and waste diversion in developments that the company manages across Canada with the objective of progressive improvement each and every year. For the Deloitte Tower, the decision was made to target a LEED Platinum certification for the Core and Shell (CS) of the building. Tenants, including Deloitte, subsequently are requested to pursue LEED for Commercial Interiors (CI) at the Gold or Platinum level. This progressive approach puts the development and its tenants at the forefront of sustainable office design in Canada.

The challenge included allowing plenty of natural daylight to reduce electric light usage, while still efficiently keeping heat gain and loss under control. The intent was to realize energy cost savings of 35-40 percent and reduced greenhouse gas emissions from lower power consumption. Other goals of the certification included sustainable site work, water conservation, indoor environmental quality, and sustainable use of materials and resources.

The Design – Abundant Daylight and Views

Early in the planning phase, the architectural teams of Kohn Pedersen Fox (KPF) Associates PC and Bregman & Hamann (B+H) Architects collaborated with glass and curtain wall fabricators to ensure the best possible selection of suitable products to optimize both the energy efficiency and the visual appeal of the building. They ultimately settled on a curtain wall design using lightly tinted gray vision glass to allow abundant daylight to enter virtually the full width and more than 80 percent of the height of the perimeter walls on all of the office floors, which also affords spectacular vistas of the city in every direction.

Gray tinted windows are an upcoming trend in architecture, according to the Efficient Windows Collaborative. Gray tinted windows offer a more reflective look from the outside of the building, while providing occupants of the building with a greater sense of transparency in the glass than would have been experienced using darker tinted windows. Based on these characteristics, Guardian Industries' AG 50 on CrystalGray™ glass was specified by the architects for the glazing.

The Performance – Optimizing Energy Efficiency with Insulating Glass

To control heat gain and loss, the Deloitte Tower's glazing is made up of dual pane IGUs with a low emissivity (low-e), gray-colored coating on the inside surfaces. The glass supplier and fabricator of the IGUs was Multiver. Throughout the planning and design process, Multiver assisted the architects with performance calculations, color selection and other support.

Multiver's staff recognized that the total performance of the glazing would be influenced not only by the glass itself, but also by the individual products that held the dual panes together, commonly referred to as glass spacers. Numerous independent tests and certification organizations have confirmed that selecting a superior glass spacer results in better performance in terms of heat transfer.

With inferior glass spacers, if the seal along the edge of the spacer does not hold up, then air and water vapor can seep into the glass space otherwise filled with an inert gas. When that happens, the glass appears streaked or stained on the inside and performs even worse. Furthermore, in cold climates like Montreal, condensation can form on the inside of the glass along the cold edges causing other problems for the adjacent building components.

Together, the architects and Multiver researched and chose glass spacers manufactured by TGI to meet the design criteria for both excellent energy efficiency and the project's unique aesthetic. Specifically, a 17/32 inch (13.44mm) TGI-Spacer was selected in a light gray tone to match the glass color.

Multiver Vice President of Operations Luc Cormier stated, "Our pre-build simulations clearly indicated that the TGI-Spacer offered superior U-Factor, vapor barrier, site-line temperature and condensation resistance – exactly the right combination of quality, value and appearance for the tower project. We simply could not achieve this any other way."

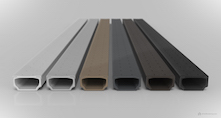

The TGI-Spacer – Unique Hybrid Spacer System

The TGI-Spacer hybrid spacer system incorporates a high-performance polymer and low-conductivity stainless steel to provide minimal heat transfer, while maximizing protection against gas leakage and moisture penetration.

The TGI-Spacer hybrid spacer system incorporates a high-performance polymer and low-conductivity stainless steel to provide minimal heat transfer, while maximizing protection against gas leakage and moisture penetration.

TGI-Spacer's straight sightline, light gray color and smooth matte finish complemented the desired overall appearance of the glazing and ultimately the whole building.

To maintain a congruent aesthetic appearance throughout all glass units, Multiver also used the TGI-Spacer in the project's spandrel glass panels. Opaque spandrel glass is used in areas that do not require vision glass, such as the horizontal sections along the floor lines, where concealing the structure and other building components was required.

Multiver fabricated the IGUs for the Deloitte Tower in a variety of sizes and shapes to meet the building design, the largest unit being 96 by 140 inches (2.4384 by 3.556 m).

The Curtain Wall System – Putting It All Together

Epsylon Concepts, Ltd. designed, engineered, manufactured and installed the curtain wall system. Epsylon is known as a leader in specialized, high energy-efficiency curtain walls, making them ideal to meet the demands of the Deloitte Tower project. The company also evaluated all of its products in regard to LEED certification for materials and vetted all products for compliance with the Living Building Challenge "Red List" of 14 potentially toxic substances.

Because of the size and expanse of the curtain wall system, a pre-fabricated, unitized system quickly was determined to be the best choice. Generally, these systems are used on mid-rise to high-rise structures that are 20,000 square feet or larger, where there is high repetition, tight job site access and high installation labor costs. These systems hold up over time better than others because each curtain wall panel is installed to be able to expand and contract independently from the supporting structure, and retain its ability to be completely weathertight.

The design team next considered traditional curtain wall systems compared to structural silicone systems. Traditional curtain wall systems use continuously gasketed, aluminum pressure plates or caps that can conduct large amounts of heat in or out of the façade, which results in "thermal bridging." Structurally glazed curtain wall systems consist of glass that is bonded or anchored back to a frame with engineered silicone sealant that can reduce or eliminate the thermal bridging along the joints between adjacent IGUs.

The aesthetic benefit of a structural silicone glazed system is the creation of greater transparency than traditional systems. There are less visual interruptions due to the lack of metal on the exterior, creating a seamless, continuous glass look. This system creates a completely clean, flush exterior appearance with superior energy performance. It can also be much more technically complex than a traditional system, so the Epsylon team was relied on heavily for its skill and quality control.

The structural silicone glazed system selected was Epsylon Platinum Series 60.075-2S, which is the highest performing curtain wall it offers. It is a pre-fabricated, unitized system with structural silicone on two sides that allows multiple glazing types and materials to be combined into one "unit" in a quality-controlled shop environment. Precision is needed in sealing the units together, since there is no outside metal frame to cover any irregularities or imperfections. This also is the same with the glass spacers, as they can be left partly exposed and create an unintended visual appearance in some cases.

The TGI-Spacer used in this project extends the colored polypropylene through an extended sidewall ensuring minimal opportunity for stainless steel peek-through and overcoming this common quality control issue on structural silicone glazed units. After the IGUs and spandrel glass are glazed into unit frames at the shop, they are transported to the job site and installed by crane. The installed units then receive additional silicone and or ethylene propylene diene monomer (EPDM) gaskets on the exterior creating "stack joints" as the complete air and moisture barrier of the system, allowing a weep at each floor.

The Result – High Design and High Performance

"The Deloitte Tower is a stunning example of design and functionality coming together beautifully by paying attention to the details of the glazing system," praised Brian Stephens, TGI market team member. "The collaborative effort of the owner, design team, fabricators and installers created an environment that eliminates visual barriers offering a desirable and productive office setting. All in all, with the goal of LEED Platinum, the Deloitte Tower certainly is a jewel for the downtown Montreal area. The TGI-Spacer played an appropriately subtle, but very important role in seeing these results achieved."

**

Deloitte Tower/La Tour Deloitte, 1115 Saint-Antoine St. W., Montreal, Quebec H3C, Canada; http://deloittetower.ca

* Owner/Developer: The Cadillac Fairview Corporation Limited; Toronto; https://www.cadillacfairview.com

* Design architect: Kohn Pedersen Fox (KPF) Associates PC; New York; https://www.kpf.com

* Architect of record: Bregman & Hamann (B+H) Architects; Toronto; http://www.bharchitects.com

* General contractor: PCL Constructors Eastern Inc.; Ottawa, Quebec; http://www.pcl.com

* Curtain wall manufacturer and installer: Epsylon Concept Inc.; Quebec, Quebec City; http://www.epsylon.ca

* Glass manufacturer: Guardian Industries Corp.; Auburn Hills, Michigan; https://www.guardian.com

* Insulating glass unit fabricator: Multiver; Quebec City, Quebec; http://www.multiver.ca

* Glazing systems' spacers: Technoform Glass Insulation (TGI) North America; Twinsburg, Ohio; http://www.glassinsulation.us

* Photos provided by: The Cadillac Fairview Corporation Limited

A member of Technoform Group, Technoform Glass Insulation (TGI) is the world leader in thermal optimized, hybrid plastic spacers for insulating glass products, including TGI®-Spacer and TGI®-Muntin products. The company innovates, develops and manufactures durable, thermal-improved edge bond solutions and special components for its customers and markets. Its manufacturing facilities are in Kassel, Germany; Milan, Italy; and Twinsburg, Ohio.

To learn more about TGI, please email TGISpacer@technoform.us, call 330-487-6600 or visit http://www.glassinsulation.us.

###

Filed under: Projects, Technoform